STRONG AND STRESS RESISTANT

SWHTM - Small Wire Harness

- estron’s twisted wires are developed and optimised for manufacturers of hearing aids and in-ear monitors (IEMs) to:

- Reduce production costs

- Get more reliable products

- Contribute to significantly fewer claims

Gain savings and less claims in the manufacturing of hearing aids and IEMs

estron SWH™ Solutions provide strength, reliability, and space efficiency

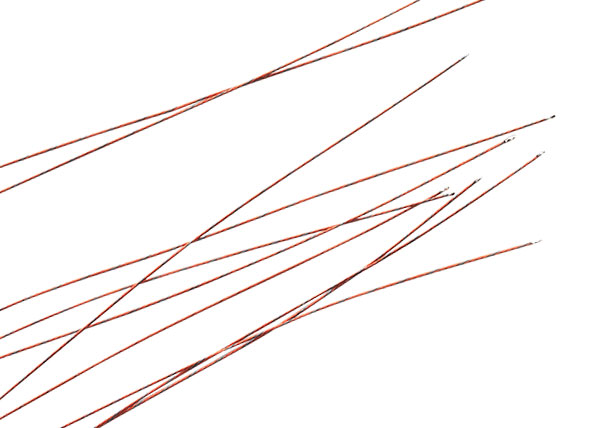

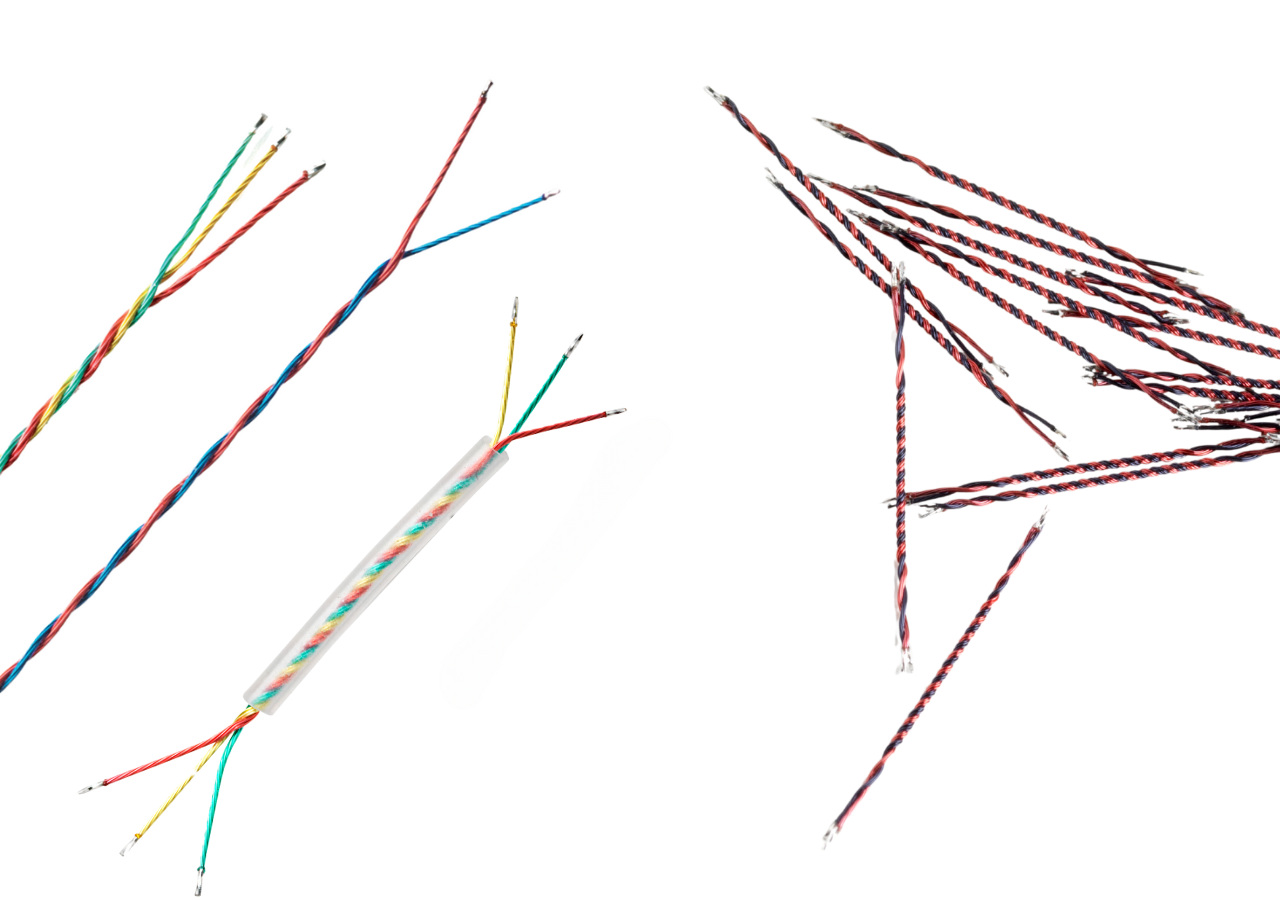

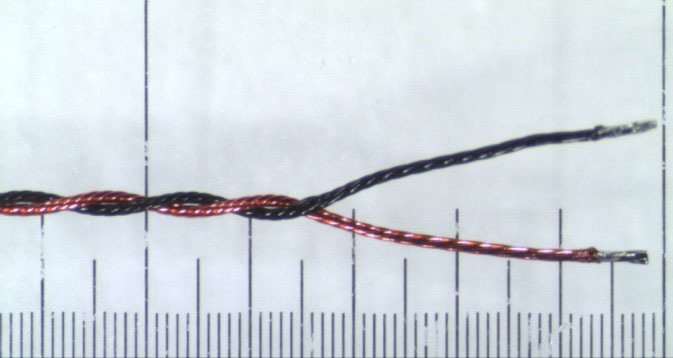

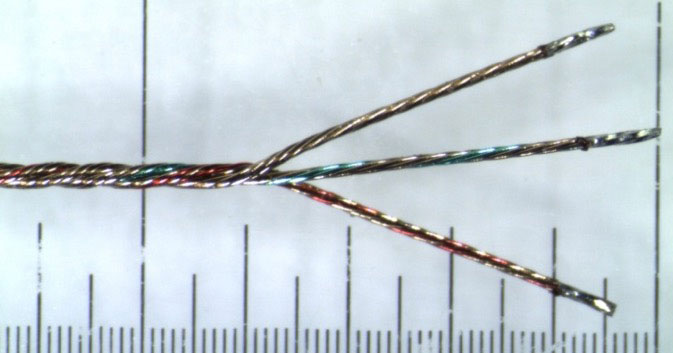

SWH™ is made from litz wires twisted together into small wire harnesses. This unique construction, where the twisted litz wires are gathered into a “bunch,” makes SWH significantly stronger and more stress-resistant than individual litz wires.

Key Benefits:

- Cost Savings: Handle and solder all litz wires in one operation instead of multiple steps, reducing time and cost.

- Fewer Claims: The stress-resistant construction of SWH results in a more reliable product.

- EMI Improvement: The twisted wire construction helps improve electromagnetic interference (EMI) performance. One conductor can be used as ground.

- Space Saving: The “stronger” construction allows for the use of finer wires, saving valuable space in your designs.

SWH wires are small, extremely reliable, colour-coded, and easy to handle during production. These features will improve your production yield and contribute to fewer returns from the market.

We also offer higher levels of subassembly, such as feeding the small wire harnesses into tubes, soldering terminals, and performing custom operations.

Examples of SWH used in audio and hearing instruments

SWH™ 2 x 7 x 0.032 mm

- Length: 46 mm

- Tinning: 0.5 mm ± 0.2 mm

- Solder: SAC 305

- Conductors: 2

- REACH & RoHS Compliant: Yes

SWH™ 3 x 6 x 0.05 mm

- Length: 46 mm

- Tinning: 0.5 mm ± 0.2 mm

- Solder: SAC 305

- Conductors: 3

- REACH & RoHS Compliant: Yes

Applications

Hearing instruments, earphones/IEMs, and other microelectronics

- Receiver In the Canal: SWH is ideal for applications where wires need to fit securely inside a tube. Available in skin colour for discrete use.

- In the Ear/In the Canal: Perfect for microphones, receivers, etc. The conductors are held together in a harness, making it easy to place inside the earplug. No need to twist wires together after soldering.

- Behind the Ear: After soldering the SWH to the components, it can be easily placed and secured into position.

Specifications:

- Material: ESW™ CuAg (also available in CPT™)

- Design/Colour: Available in several designs and colours

- Type: Standard and custom options available

- Compliance: RoHS, REACH compliant

Different litz wires for different scenarios

Different types of estron litz wires

ESW™

High performance - the most popular

XT-ESW™

Highest performance - thinnest and strongest

CPT™