.

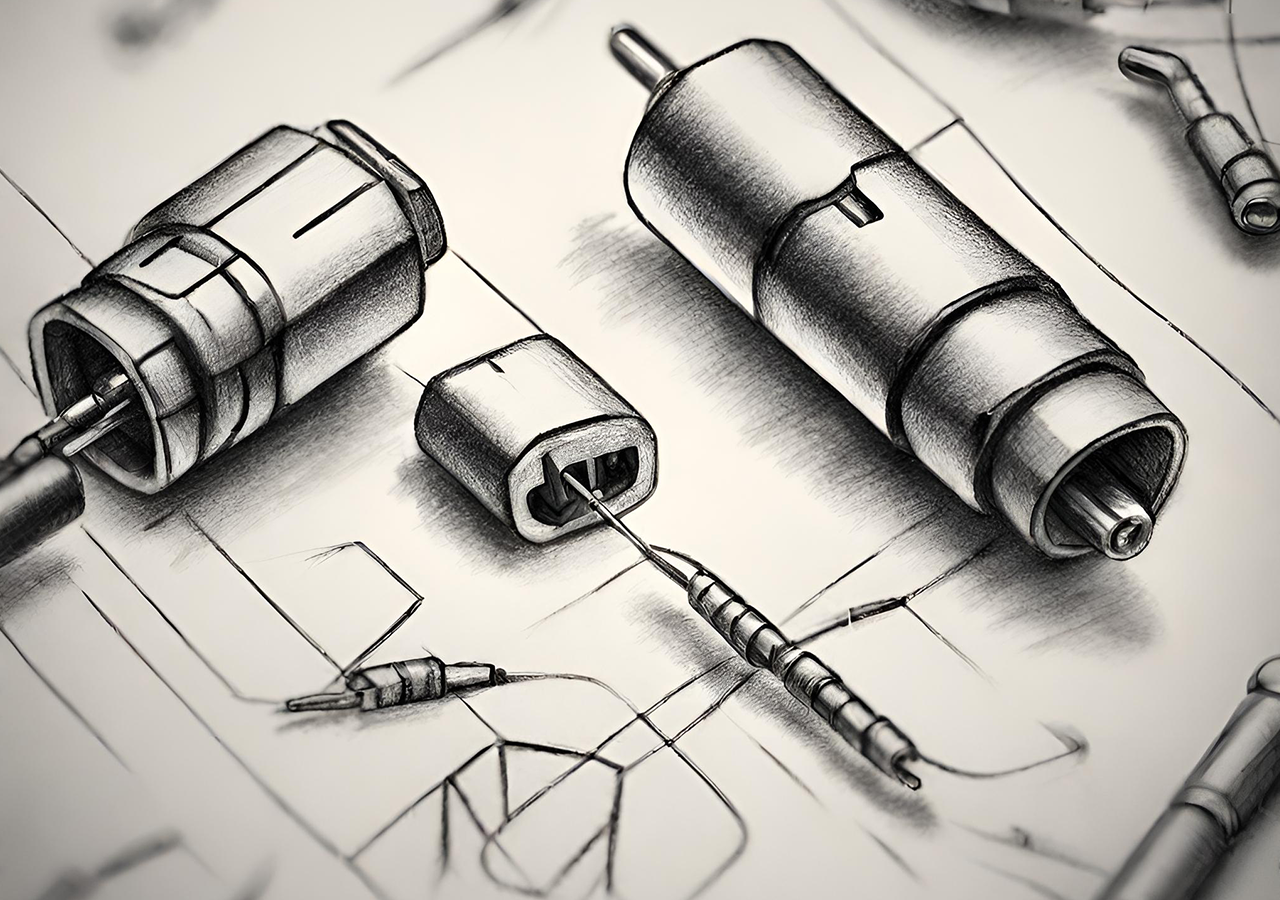

MINIATURE LITZ WIRES, CABLES, AND CONNECTORS

Stay on top of the game

Unlock new ideas

- Idea generation and problem solving

- Design for manufacturing

- Scalable production

.

.

NEVER LOSE THE MOMENT

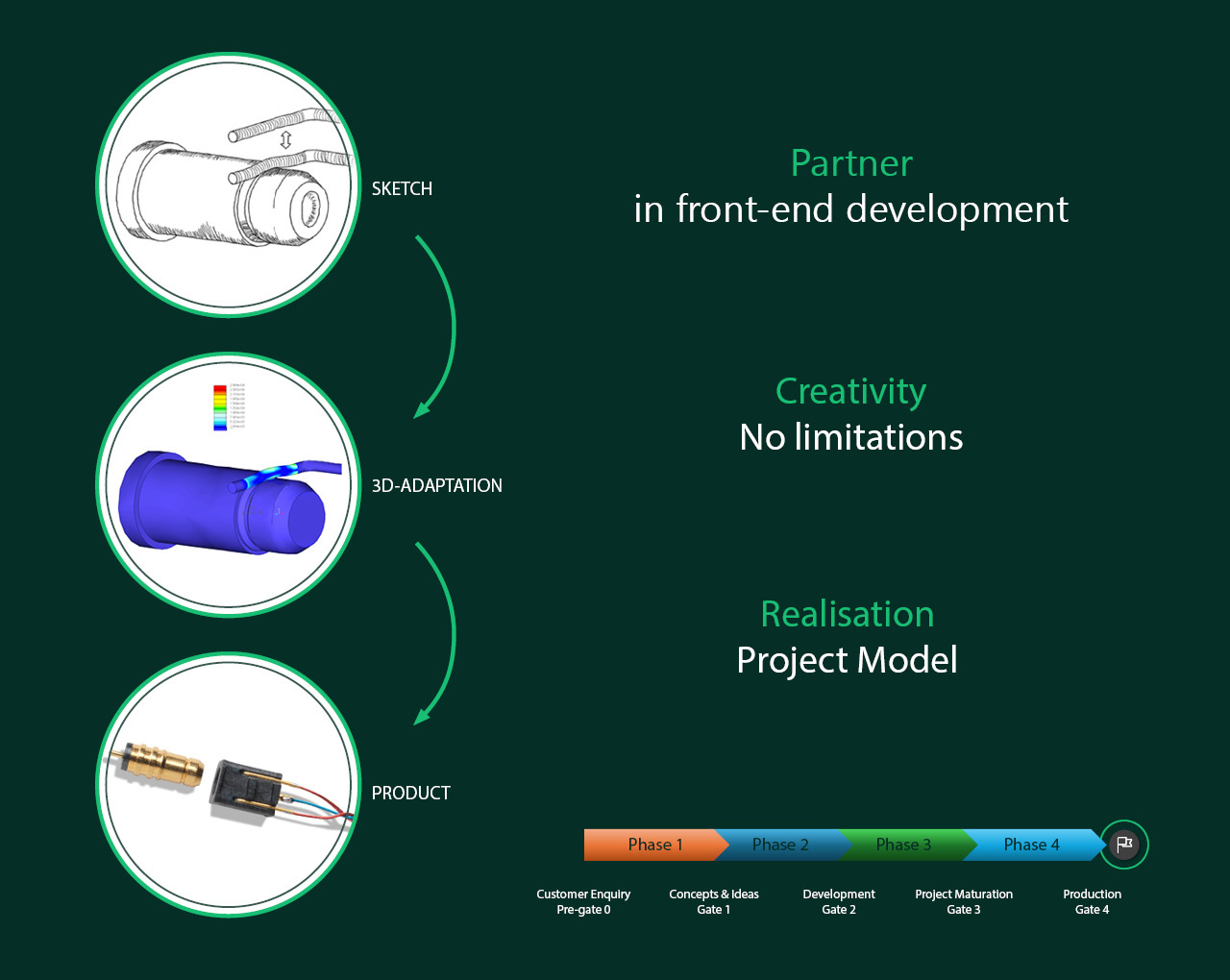

Co-development and design for manufacturing

Innovative Circular Solutions

- Expert ideation and creative facilitation

- Online and on-site co-development

- Knowledge sharing and integration

Scalable Manufacturing Design

- Secure form, fit, and function

- Supply of 50M+ low-risk assembly plug cables

- In-house developed automated precision equipment

Flexibility and Agility

- Adaptable development and production

- Flexible production capacity

- Reliable high-quality supply

Core processes

Over moulding of cables, glue bodies, pins, and PCBs. Ultrafine details with Poka-yoke, tactility, and haptic feedback. Tight tolerances and precision over moulding of micro assemblies

In collaboration with sub-suppliers. we deliver micro components with a combination of plastics and metals. Opportunities within size/weight reduction, design flexibility and reliability

Precision gluing on micro assemblies. Tight and leak free. Experience within epoxy, and cyanoacrylate both by curing with UV-light, 2k, room- and elevated temperatures etc.

Lead-free solder. Tight tolerances and short tinning lengths. With semi-automatic/manual operations all kind of soldering is possible. Soldering small terminals in <0.3 s

High concentricity ultrathin es-Linum® cables with 2, 3, 6, 8 and 12 conductors with/without fibre reinforcement. Outer diameter 0.6 or 0.9 mm. Different shore options

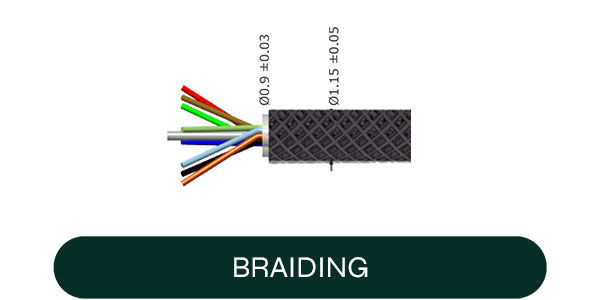

For a more robust cable we offer cable solutions with a polyester braiding. The diameter of a braided cable is from 1.15 mm. Unlimited colour possibilities

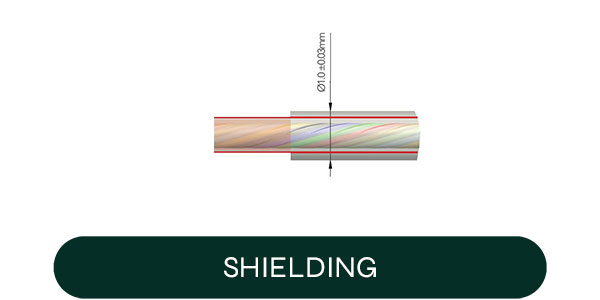

Unique thin shielded cable with outer diameter of 1.0 to 1.4 mm. Flexible, durable, formable self-recovering and electrically conductive layer. Cost-effective with an impedance of 7.5 Ω/m

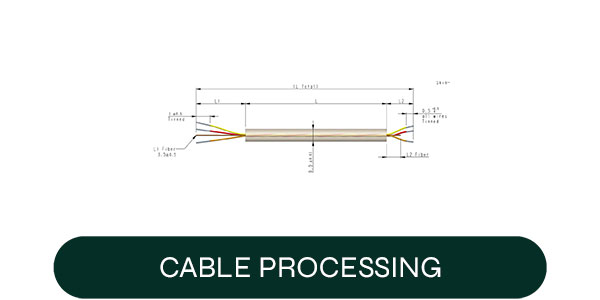

Cut (±0.2 mm), strip (±0.5 mm) and tinning (+0.5 mm/-0 mm) with tight tolerances. We fulfil custom made requirements with our semi-automatic processes

Proven reliable anchoring of cables/connectors. Securing the connection when the cable is pulled/turned/bended. Customised geometry of the anchoring area is an option

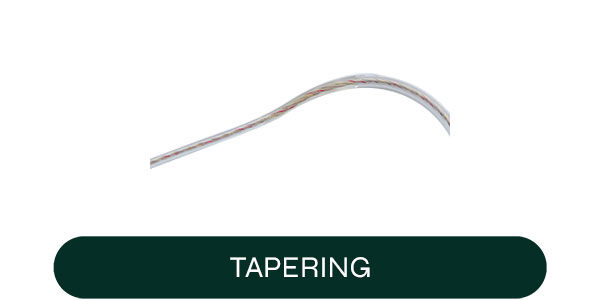

Fusion process for tapered transition tubes and strain relief elements making a smooth and highly durable transition from connector to cable

Thermoforming of cables in both 2D and 3D shapes qualifying to high demands. Thermoforming such as coil shapes is also possible. Excellent built-in shape memory.

With our fully automated processes we do precision cutting and tinning of ultrafine litz wires from 25-200 µm single/twisted wires with tinning length down to 0.3 ± 0.2 mm

Small Wire Harnesses of ultrafine litz wires with multiple robust combinations. Performed on inhouse built machinery. Two-for-one, and concentric twisting machines

.

Competent and dedicated tech and development team

Get in touch

Different backgrounds from Sound engineers to Master in Chemical engineering, Marine engineer, Mechanical engineers, and Technicians, are just some of the titles behind the very competent and dedicated team you get to work with.

We assign a primary contact in all projects, making it easy for you. Get in touch with the right expert through our sales team if you need sparring on your ideas or projects.